Process of Production

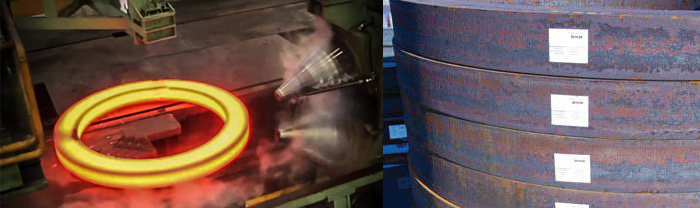

Imported seamless rolled rings (forged rings) are primarily used in our production.

Our company imports raw materials from many different suppliers in Europe, has a wide supplier network in this regard.

Raw materials are used in our standard manufacturing, are imported with material analysis reports and EN10204 3.1 Certificates and these are matched with serial numbers and are recorded to correspond traceability in standard of quality.

In special manufacturing as per the usage areas; the raw materials with the following certifications (EN10204 3.2) are also procured.

- Bureau Veritas

- I.S.P.E.S.L.

- Lloyd’s Register of Shipping

- T.U.V.

- Det Norske Veritas

- Germanischer Lloyd

- American Bureau of Shipping

- RINA

Bending material may also be used for small diameter products called as light series according to the usage areas, bending and normalization operations of referred material are performed in our own facilities.

Tibet Makina, which exports 40% of its production worldwide, is dedicated to providing high-quality manufacturing to international companies.

Total Area

18000m²

Production Capacity

Max Ø4500mm

Min Ø150mm

TİBET MAKİNA has the ability to apply different kinds of coating on slewing rings and bearings according to industrial needs. Main purpose of coating is increasing resistance of the surface against environmental conditions so increasing strength.

COATING TYPES AT TİBET MAKİNA

-

Hard Anodizing Coating

Reservoir Sizes: 4000 x 4000 x 200 mm

According to:

MIL-STD-8625 Tip-III Class- I, Hard Anodizing Coating Standard

MIL-STD-8625 Tip II Class- I, Anodizing Coating Standard -

Sand Blasting

According to: DIN 8567 with ISO 8501-1 Standard -

Zinc Spray Coating

Reservoir Sizes: Rings up to Ø3200 mm dia

According to: EN 22063 Standard -

Manganese Phosphatizing

Reservoir Sizes: 2300 x 1200 x 550 mm

According to: TS EN 12476 Standard -

Zinc Dichromate Coating

According to: TS EN 2081 Standard Metalic and other inorganic coatings. Repairment on ferrous and stainless material with zinc electrolytic coating -

Chemical Passivating

According to: ASTM A967-05EZ Chemical Passivating for stainless steel -

Chromate Coating on Aluminum Gear Surface

According to: MIL-STD-C-5541, Class 1 Standard -

Hard Chrome Coating

According to: Hard chromium corrosion resistance control TS EN 10289

Military Standards: MIL-P-8585 (TT-P1757) Zinc chromate primer

MIL-C-8514

MIL-C-83286

The surfaces, where the bearing is assembled to the machine, should definitely be smooth and processed. The factors that will prevent the bearing from rotating, such as welding tensions, dye accumulations or burr etc., have to be removed definitely. The surface flatness should definitely be checked before the assembly.

The Surface Flatness tolerances in relation therewith are indicated in Table 1.

The products such as filling materials, shims etc. should definitely not be used in the mounting. After the bearing is assembled to the surface, it should be rotated a few turns and it should be checked whether there is any clamping.

During the assembly, 10.9 bolt in compliance with DIN 267 should be used and it should be screwed at the tolerances as indicated in Table 2. The screwing operation should be performed as indicated in Figure 1.

Friction torque test

High temperature test (+55°C)

Low temperature test (-32°C)

Humidity test

Rain test

Airtightness test

Liquid penetration test

Inclination test

Axial load test

Radial load test

Clearance test

Elastic deformation test

Mastery in Measurement, Quality in Production

The Dea delta slant performance 3D coordinate measuring machine is a 3-axis CNC-controlled coordinate measuring machine that operates with portal technology.

X axis max. 3000mm

Y axis max. 5100mm

Z axis max. 2000mm

The standard packaging type provides protection up to 2 years in room temperature.

After the external surface of the bearing is covered with the protective grease TECTYL 506 or OKS 500, the bearing is packed by being wrapped with a special dehumidifier protective paper. The product is made ready for shipment by means of being fixed on a wooden palette.

Pursuant to the qualification of the product to be shipped and the demand of the customer, special carriage apparatus or special cases may also be made.