Corporate

Imported seamless rolled rings (forged rings) are primarily used in our production.

Our company importing raw materials from many different suppliers in Europe, has a wide supplier network in this regard.

Raw materials used in our standard manufacturing, are imported with material analysis reports and EN10204 3.1 Certificates and these are matched with serial numbers and are recorded to correspond traceability in standard of quality.

In special manufacturing as per the usage areas; the raw materials with the following certifications (EN10204 3.2) are also procured.

Bending material may also be used for small diameter products called as light series according to the usage areas, bending and normalization operations of referred material are performed in our own facilities.

TİBET MAKİNA has ability to different kinds of coating on slewing rings and bearings according to industrial needs. Main Purpose of coating is increasing resistance of the surface against enviromental conditions so increasing strength.

COATING TYPES AT TİBET MAKİNA

Reservoir Sizes: 4000 x 4000 x 200 mm According to; MIL-STD-8625 Tip-III Class- I, Hard Anodizing Coating Standart MIL-STD-8625 Tip II Class- I, Anodizing Coating Standart

According to; DIN 8567 with ISO 8501-1 Standart

Reservoir Sizes: Rings up to Ø3200 mm dia According to; EN 22063 Standart

Reservoir Sizes: 2300 x 1200 x 550 mm According to; TS EN 12476 Standart

According to; TS EN 2081 Standart Metalic and other inorganic coatings. Repairment on ferrous and stainless material with zinc electrolitic coating

According to; ASTM A967–05E2 Chemical Passivating for stainless steel

According to; MIL-STD-C-5541, Class1 A standart

According to; Hard chromium corrosion resistance control TS EN 10289

Military Standarts:

MIL-P-8585 (TT-P1757) Zinc chromate primer

MIL-C-8514

MIL-C-83286

The surfaces, where the bearing is assembled to the machine, should definitely be smooth and processed. The factors that will prevent the bearing from rotating, such as welding tensions, dye accumulations or burr etc. has to be removed definitely. The surface flatness should definitely be checked before the assembly.

The Surface Flatness tolerances in

relation therewith are indicated in

Table 1.

| SURFACE FLATNESS TOLERANCES | |||

| Track Diameter (mm) |

Single Row Ball Bearing |

Double Row Ball Bearing |

Roller Bearing |

| 0-500 | 0.10 | 0.15 | 0.07 |

| 500-1000 | 0.15 | 0.20 | 0.10 |

| 1000-1500 | 0.19 | 0.25 | 0.12 |

| 1500-2000 | 0.22 | 0.30 | 0.15 |

| 2000-2500 | 0.25 | 0.35 | 0.17 |

| 2500-4000 | 0.30 | 0.40 | 0.20 |

The products such as filling materials,

shims etc. should definitely not be used

in the mounting. After the bearing is

assembled to the surface, it should be

rotated a few tours and it should be

checked whether there is any clamping.

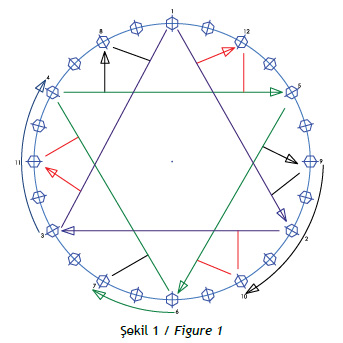

During the assembly, 10.9 bolt in compliance with DIN 267 should be used and it should be screwed at the tolerances as indicated in Table 2. The screwing operation should be performed as indicated in Figure 1.

| TORQUE VALUES FOR BOLTS | ||||||

| Anma Çapı | 8.8 | 10.9 | 12.9 | |||

| Diameter (Metric) | Tork (Nm) | FM (N) | Tork (Nm) | FM (N) | Tork (Nm) | FM (N) |

| M6X1 | 10.00 | 9000 | 14.00 | 13200 | 16.00 | 15400 |

| M8X1,25 | 23.00 | 16500 | 34.00 | 24200 | 40.00 | 28500 |

| M10X1,5 | 45.00 | 26000 | 67.00 | 38500 | 77.00 | 45000 |

| M12X1,75 | 80.00 | 38500 | 115.00 | 56000 | 135.00 | 66000 |

| M14X2 | 125.00 | 53000 | 185.00 | 77000 | 215.00 | 90000 |

| M16X2 | 195.00 | 72000 | 285.00 | 106000 | 335.00 | 124000 |

| M18X2,5 | 280.00 | 91000 | 395.00 | 129000 | 465.00 | 151000 |

| M20X2,5 | 395.00 | 117000 | 560.00 | 166000 | 655.00 | 194000 |

| M22X2,5 | 540.00 | 146000 | 770.00 | 208000 | 900.00 | 243000 |

| M24X3 | 680.00 | 168000 | 970.00 | 239000 | 1130.00 | 280000 |

| M27X3 | 1000.00 | 221000 | 1420.00 | 315000 | 1670.00 | 1670.00 |

| M30X3,5 | 1360.00 | 270000 | 1930.00 | 385000 | 2260.00 | 450000 |

| M33X3,5 | 1850.00 | 335000 | 2630.00 | 480000 | 3080.00 | 560000 |

| M36X4 | 2380.00 | 395000 | 3380.00 | 560000 | 3960.00 | 660000 |

The hardness range is an area between the place where the hardening in the bearing race starts and the place where the hardening in the bearing race ends. It is identified and marked with the letter (S). The marking is made during the assembly to the places to be easily seen outside the surface flatness of the bearing or to the plug place.During the assembly, the referred area should stay outside the main load bearing areas.

Despite geometrically proper profiles and theoretically sufficient gears, it is possible to have meshing / clutching problems under high stress.

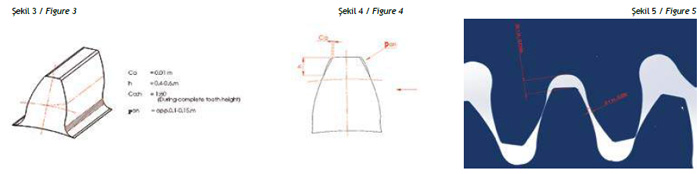

As shown in figure 3 at the flank of gear there is ‘’chipping’’ or ‘’scuffing’’. This situation occurs especially in gears with hardened pinions where the pinion tip edges scrape the gear. It may happen due to a various reasons.

Most driving units are mounted as suspended from above. Therefore, it is impossible to prevent the deviation at the pinion shaft high forces

cause elastic deformation at the interface of the driving unit and mounting structure, which results in meshing problems as well. Also direct

contact between two materials increase the chipping effect.

Previous damages can be corrected through providing a radius at pinion tip and pinion flanks. Decreasing the pinion tip is usually a solution to reduce the vibration (noise) effects of gear mechanism that operate at high velocity. Some decreases at excessive loading conditions can be done according to following formulas obtained through researches:

The space between pinion and gear is calculated according to Figure 5.

During the mounting process, gears and pinion should be adjusted from the place where gear painted in blue.

The standard packaging type provides protection up to 2 years in room temperature.

After the external surface of the bearing is covered with the protective grease TECTYL 506 or OKS 500, the bearing is packed by being wrapped with a special dehumidifier protective paper. The product is made ready for shipment by means of being fixed on a wooden palette.

Pursuant to the qualification of the product to be shipped and the demand of the customer, special carriage apparatus or special cases may also be made.